Basic Info.

OEM Service

Yes

Drawings

Yes

Peen Shoted

Yes

Passivation

Yes

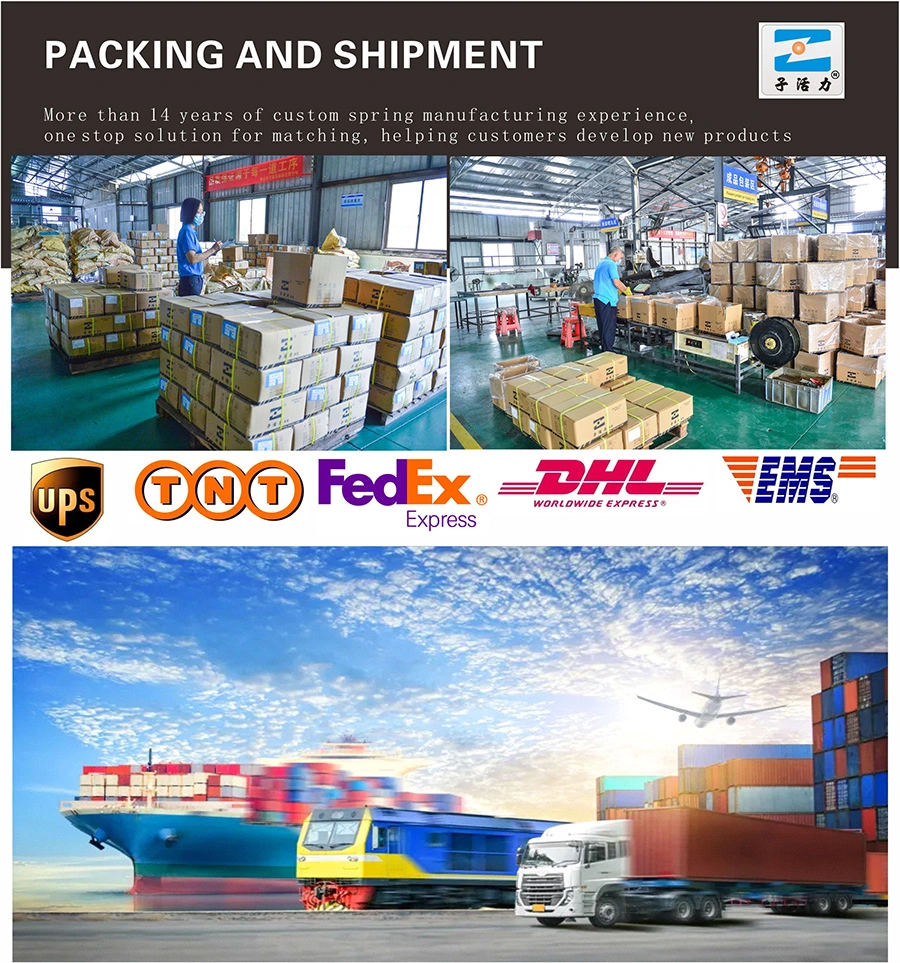

Transport Package

Custom as Requirements

Specification

Custom as requirements

Trademark

Custom as requirements

Origin

China

HS Code

7320209000

Production Capacity

80000000/Week

Product Description

Electric Automatic Sectional Overhead Garage Door Torsion Spring

Zihuoli manufacturer, supplier and exporter a qualitative range of Coil Springs. Coil springs are precisely engineered using latest machinery at our well-equipped infrastructure. Zihuoli offer these Coil Springs various types of material sections like flat, square, round and rectangular.

Product Description

Product Description

What is Compression spring?

Compression Springs are open-coil helical springs wound or created to oppose compression along the axis of wind. Helical Compression is the most typical steel springtime arrangement. These coil springs can function individually, though commonly assembled over a guide rod or equipped inside an opening.

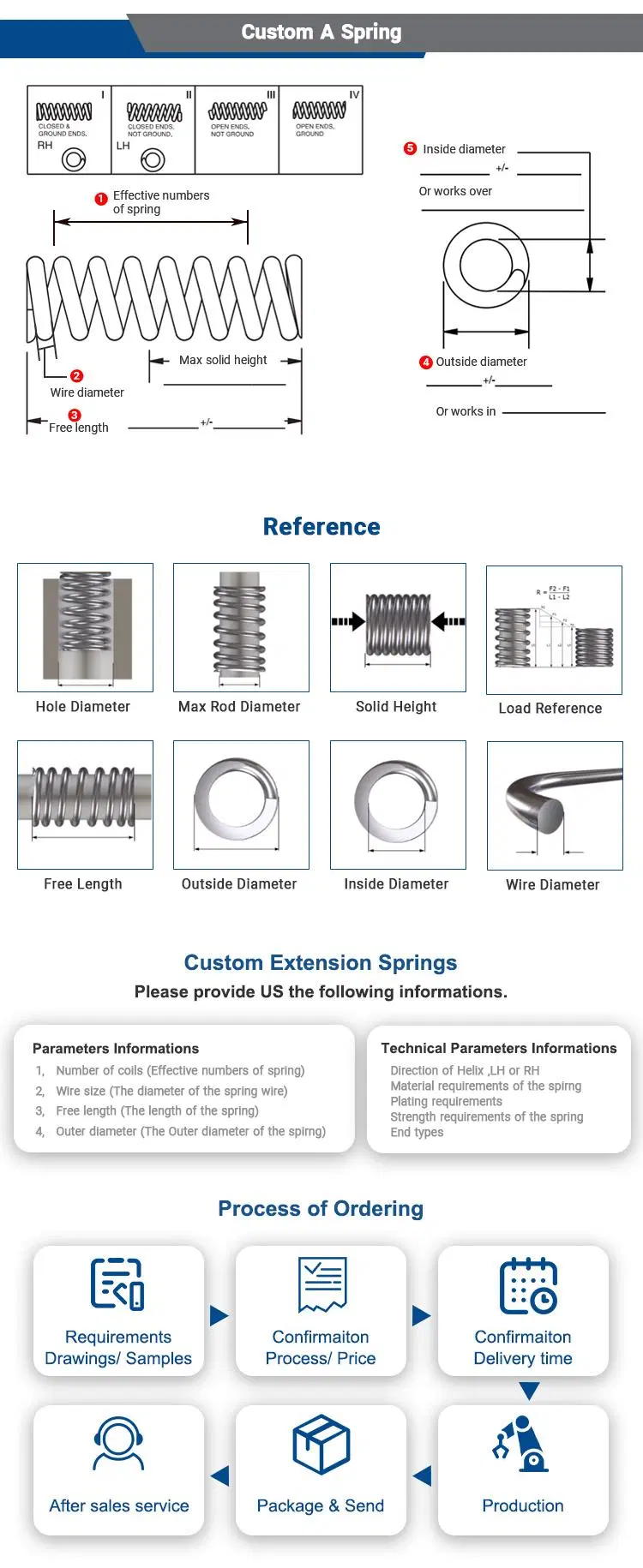

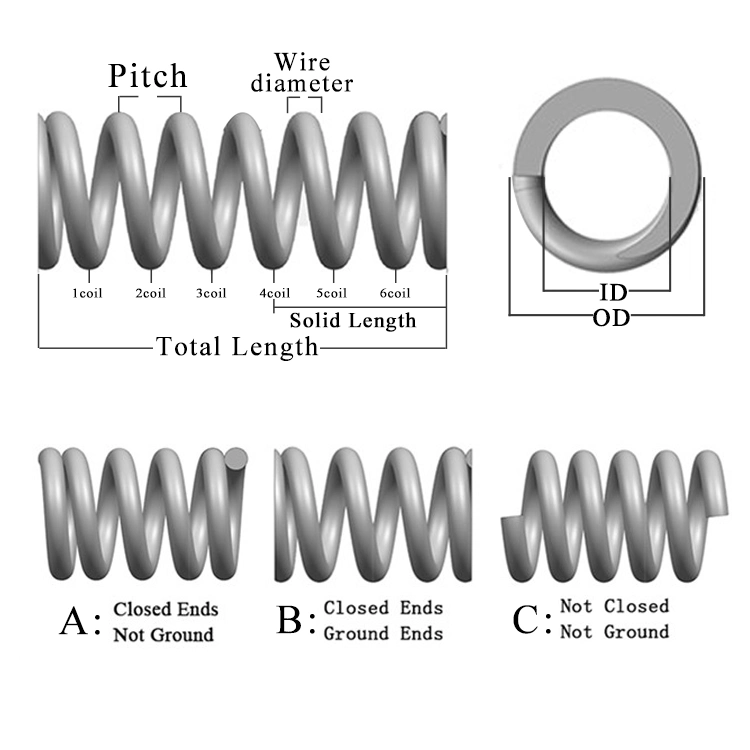

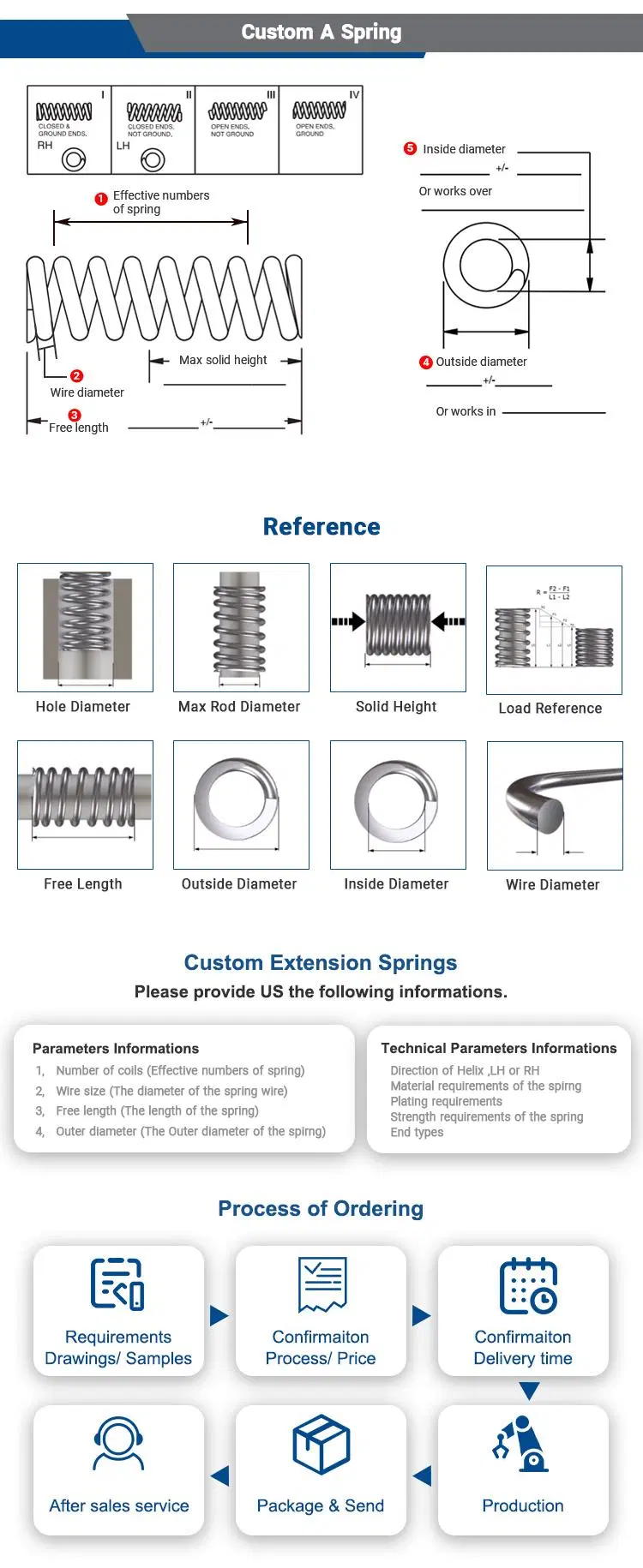

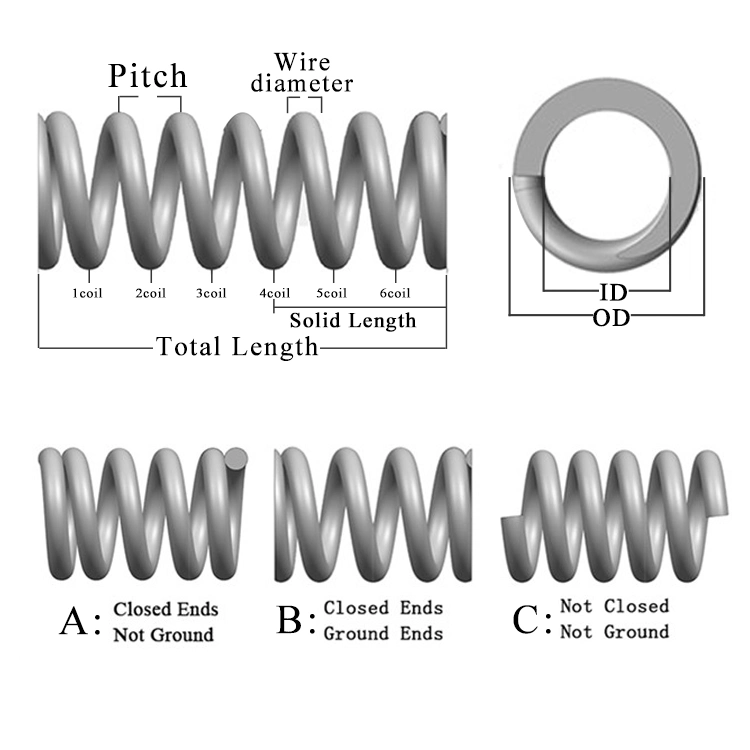

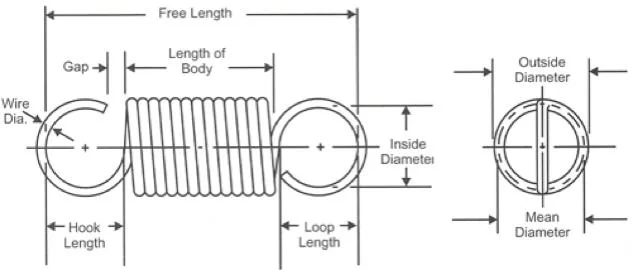

Typical Compression Spring Design Terms

According to the Spring Manufacturers Institute Handbook of Spring Design, commonly used compression spring terminology includes the following:

Wire diameter (d)

Outside Diameter (O.D)

Inside Diameter (ID)

D coil diameter =Outside Diameter. (O.D. + I.D.)/2 or O.D. - d

Free Length = The total length of a compression spring when it is unloaded.

Pitch (P )= the distance between the wire centers in adjacent active coils. It is best practice to specify the number of active coils rather than the pitch.

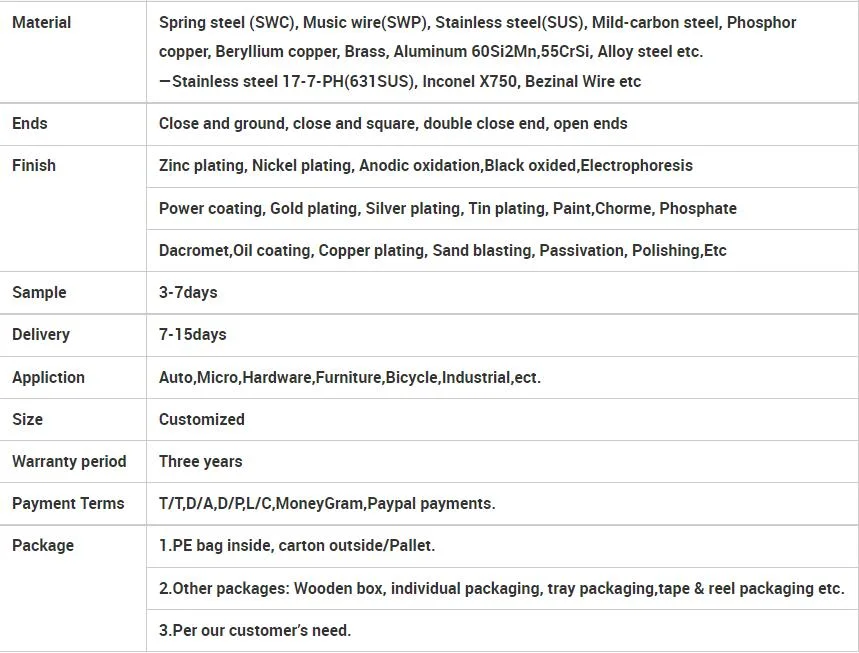

Compression Spring Materials

Zihuoli Spring custom compression springs from a variety of materials. Music wire, hard drawn, stainless steel (type 302, type 316), oil tempered, chrome silicon, and phosphor bronze are the most common material types for compression springs. We also make compression springs out of more exotic materials like Inconel, Monel, Beryllium Copper, and others.

In order to provide our customers with the shortest lead times possible, we stock several of these material types in various diameters.

Compression spring materials that are commonly used include:

• Carbon Steel

• Stainless steels

• Alloy steel

• Copper Base Alloy

• Nickel Base Alloy

• Cobalt-Nickel

• Titanium

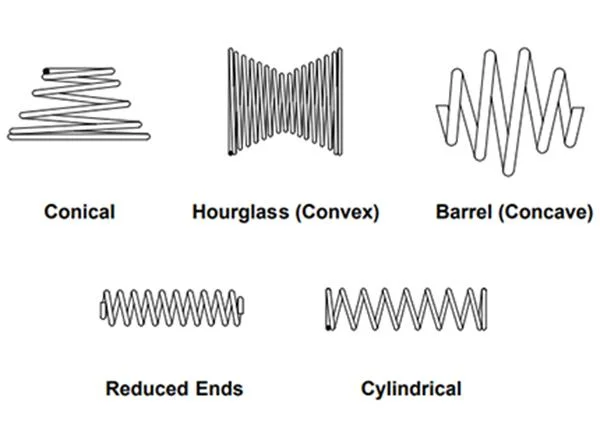

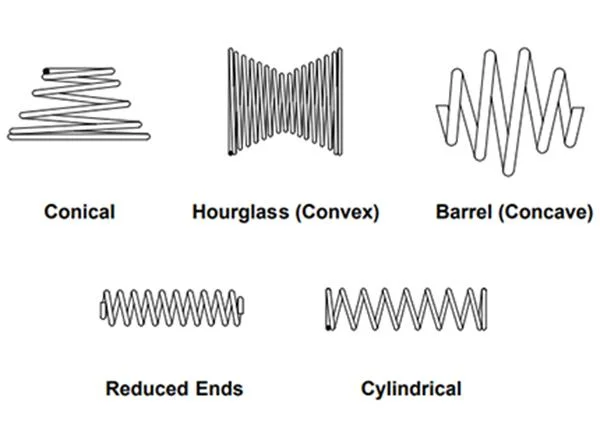

Zihuoli Springs Capability for Different Compression Spring Body Shapes

There are four different body designs for compression springs are produced by Zihuoli Spring.

Zihuoli Spring is a leading manufacturer of Custom Spring. We manufacture various springs related tests and test reports: 1. Spring strength test: we have a variety of automatic spring testing machines, which can test the force, tensile strength, bending strength, compressive strength, elastic modulus, fracture elongation, yield strength and other data of spring products. The load accuracy can reach ± 0.01%, which reach GB and international standards such as ISO, JIS, ASTM and din. Salt spray test can be carried out by Salt spray test machine. We will test the corrosion resistance after the surface treatment, such as coating, electroplating, organic and inorganic film, anode treatment, rust proof oil and other anti-corrosion treatment so as to establish the quality of the product.

Zihuoli Spring is a leading manufacturer of Custom Spring. We manufacture various springs related tests and test reports: 1. Spring strength test: we have a variety of automatic spring testing machines, which can test the force, tensile strength, bending strength, compressive strength, elastic modulus, fracture elongation, yield strength and other data of spring products. The load accuracy can reach ± 0.01%, which reach GB and international standards such as ISO, JIS, ASTM and din. Salt spray test can be carried out by Salt spray test machine. We will test the corrosion resistance after the surface treatment, such as coating, electroplating, organic and inorganic film, anode treatment, rust proof oil and other anti-corrosion treatment so as to establish the quality of the product.

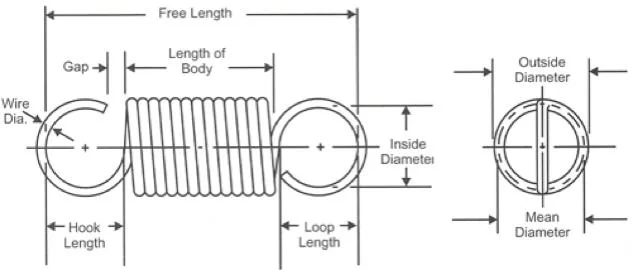

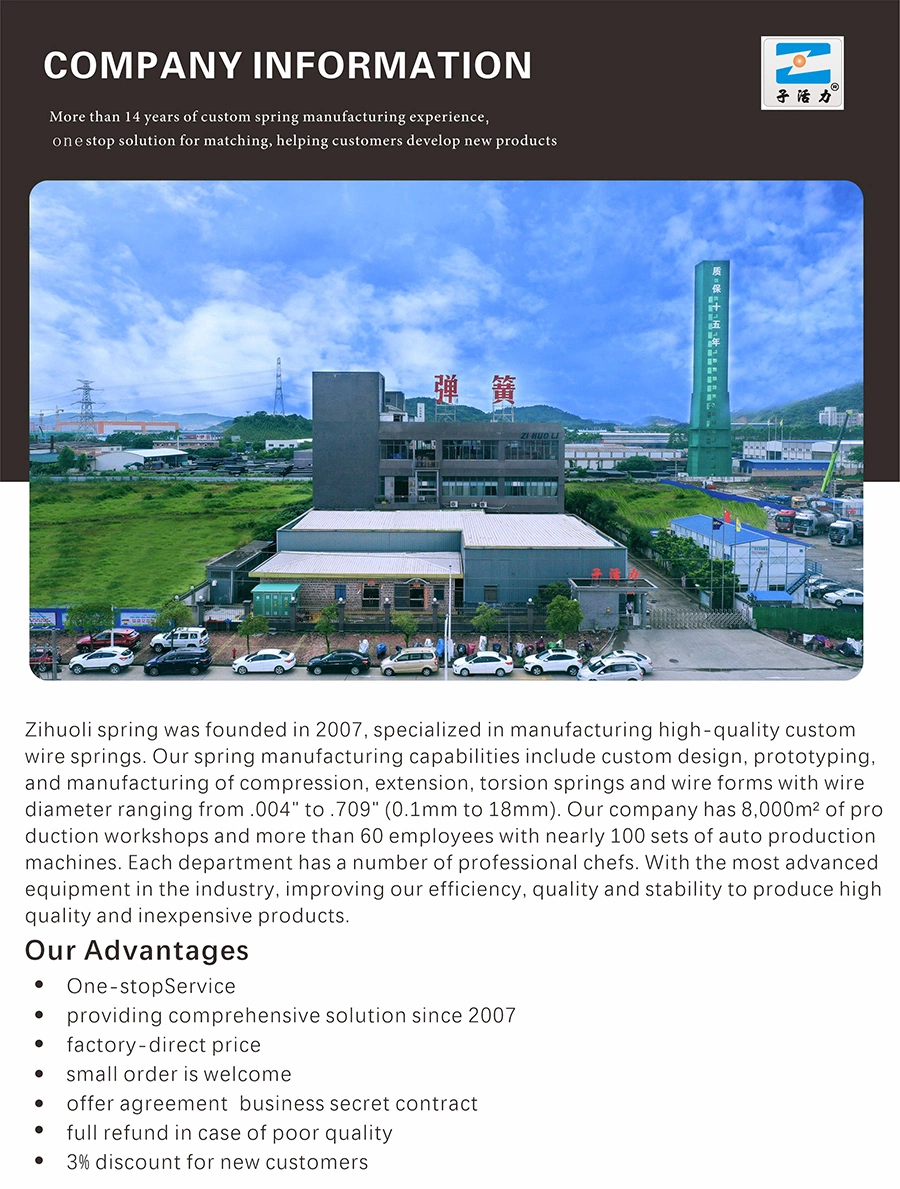

Established in the year of 2007, Zihuoli Spring are engaged in manufacturing and supplying wide assortment of Various Kinds of Extension Spring. We source the quality material for manufacturing our products from reliable vendors of the market. Our products are available as per the industry standards and in accurate dimensions.

Established in the year of 2007, Zihuoli Spring are engaged in manufacturing and supplying wide assortment of Various Kinds of Extension Spring. We source the quality material for manufacturing our products from reliable vendors of the market. Our products are available as per the industry standards and in accurate dimensions.

FAQ

FAQ

1.Do you offer custom service?

Yes, it's our job, send us your specification or drawings, and we will make you perfect products. Or tell us your idea for

getting a design from us.

2.What's your main products?

Compression Spring, Extension Spring, Torsion Spring, Wire Forming Spring, Stamping Parts and so on

3.How about the Processing Craft?

Material-purchased- Producing-First testing-Coiling-Inspection-Heat treatment-Cleaning-Surface treatment- Final testing-Packing-shipping

4.How about your Supply Capacity?

7000,000-9000,000pcs/week

Zihuoli manufacturer, supplier and exporter a qualitative range of Coil Springs. Coil springs are precisely engineered using latest machinery at our well-equipped infrastructure. Zihuoli offer these Coil Springs various types of material sections like flat, square, round and rectangular.

Product Description

Product Description

Product Description

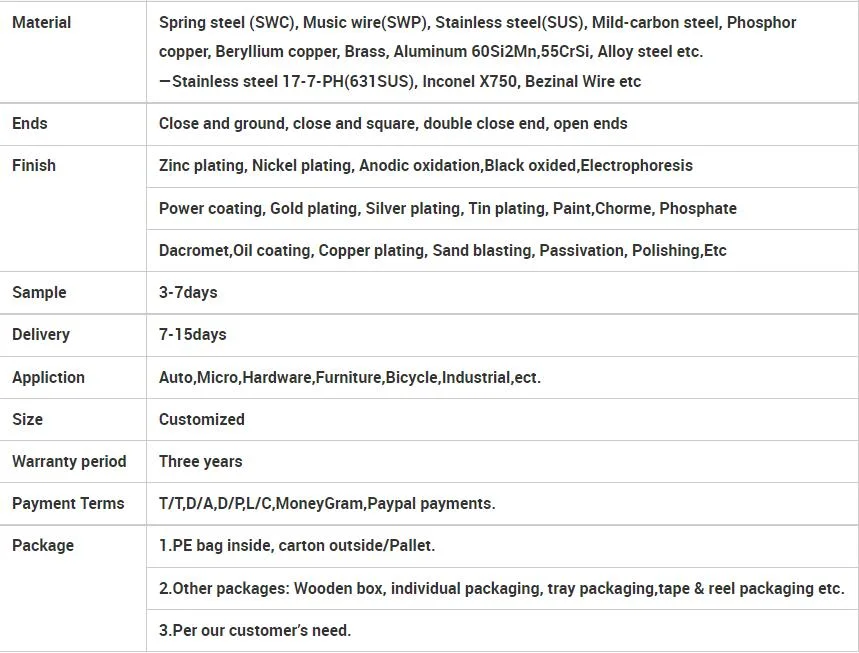

| SPECIFICATION: | |

| Material | Stainless steel, carbon steel, spring steel, alloy spring steel, refractory steel, brass, metal, bronze, etc. |

| Wire diameter | 0.01~10.0mm |

| Finish | Zinc, nickel, chrome, silver, gold, imitation gold plating or as request |

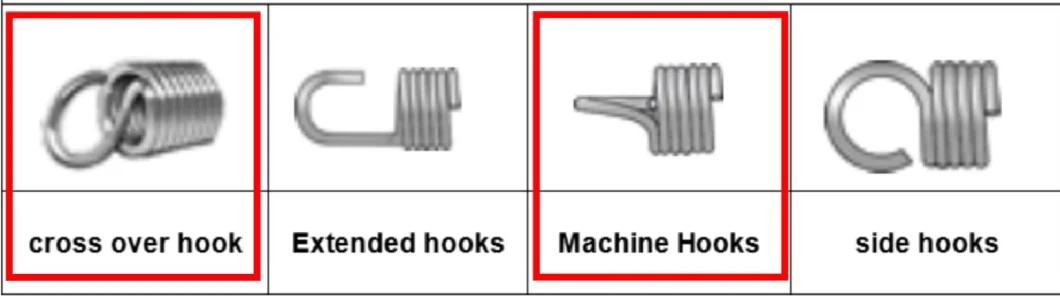

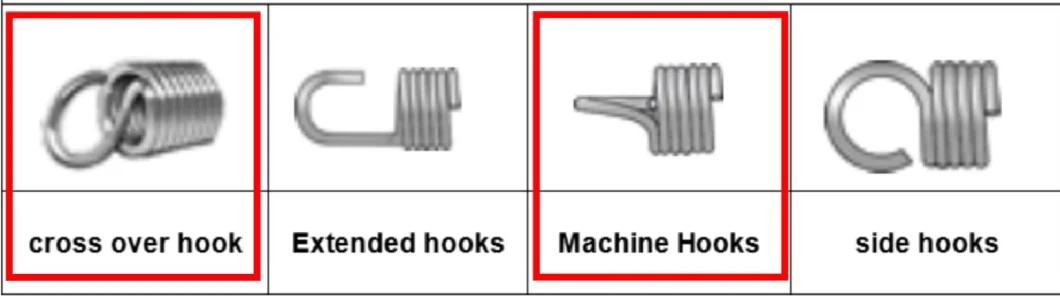

| Styles of ends | Straight/short hook/double torsion/hinge/straight torsion/special |

| Load | Our computer program can assist you based on the load design |

| OEM & ODM | Acceptable |

What is Compression spring?

Compression Springs are open-coil helical springs wound or created to oppose compression along the axis of wind. Helical Compression is the most typical steel springtime arrangement. These coil springs can function individually, though commonly assembled over a guide rod or equipped inside an opening.

Typical Compression Spring Design Terms

According to the Spring Manufacturers Institute Handbook of Spring Design, commonly used compression spring terminology includes the following:

Wire diameter (d)

Outside Diameter (O.D)

Inside Diameter (ID)

D coil diameter =Outside Diameter. (O.D. + I.D.)/2 or O.D. - d

Free Length = The total length of a compression spring when it is unloaded.

Pitch (P )= the distance between the wire centers in adjacent active coils. It is best practice to specify the number of active coils rather than the pitch.

Compression Spring Materials

Zihuoli Spring custom compression springs from a variety of materials. Music wire, hard drawn, stainless steel (type 302, type 316), oil tempered, chrome silicon, and phosphor bronze are the most common material types for compression springs. We also make compression springs out of more exotic materials like Inconel, Monel, Beryllium Copper, and others.

In order to provide our customers with the shortest lead times possible, we stock several of these material types in various diameters.

Compression spring materials that are commonly used include:

• Carbon Steel

• Stainless steels

• Alloy steel

• Copper Base Alloy

• Nickel Base Alloy

• Cobalt-Nickel

• Titanium

Zihuoli Springs Capability for Different Compression Spring Body Shapes

There are four different body designs for compression springs are produced by Zihuoli Spring.

- straight cylindrical compression spring

- Conical or tapered compression springs,

- barrel compression springs,

- hourglass compression springs,

Zihuoli Spring is a leading manufacturer of Custom Spring. We manufacture various springs related tests and test reports: 1. Spring strength test: we have a variety of automatic spring testing machines, which can test the force, tensile strength, bending strength, compressive strength, elastic modulus, fracture elongation, yield strength and other data of spring products. The load accuracy can reach ± 0.01%, which reach GB and international standards such as ISO, JIS, ASTM and din. Salt spray test can be carried out by Salt spray test machine. We will test the corrosion resistance after the surface treatment, such as coating, electroplating, organic and inorganic film, anode treatment, rust proof oil and other anti-corrosion treatment so as to establish the quality of the product.

Zihuoli Spring is a leading manufacturer of Custom Spring. We manufacture various springs related tests and test reports: 1. Spring strength test: we have a variety of automatic spring testing machines, which can test the force, tensile strength, bending strength, compressive strength, elastic modulus, fracture elongation, yield strength and other data of spring products. The load accuracy can reach ± 0.01%, which reach GB and international standards such as ISO, JIS, ASTM and din. Salt spray test can be carried out by Salt spray test machine. We will test the corrosion resistance after the surface treatment, such as coating, electroplating, organic and inorganic film, anode treatment, rust proof oil and other anti-corrosion treatment so as to establish the quality of the product.

Established in the year of 2007, Zihuoli Spring are engaged in manufacturing and supplying wide assortment of Various Kinds of Extension Spring. We source the quality material for manufacturing our products from reliable vendors of the market. Our products are available as per the industry standards and in accurate dimensions.

Established in the year of 2007, Zihuoli Spring are engaged in manufacturing and supplying wide assortment of Various Kinds of Extension Spring. We source the quality material for manufacturing our products from reliable vendors of the market. Our products are available as per the industry standards and in accurate dimensions.

FAQ

FAQ 1.Do you offer custom service?

Yes, it's our job, send us your specification or drawings, and we will make you perfect products. Or tell us your idea for

getting a design from us.

2.What's your main products?

Compression Spring, Extension Spring, Torsion Spring, Wire Forming Spring, Stamping Parts and so on

3.How about the Processing Craft?

Material-purchased- Producing-First testing-Coiling-Inspection-Heat treatment-Cleaning-Surface treatment- Final testing-Packing-shipping

4.How about your Supply Capacity?

7000,000-9000,000pcs/week